COVER GLASS Relevant:

The shape of COVER GLASS should not be too heteromorphic as far as possible. The more heteromorphic the appearance, the greater the impact strength.

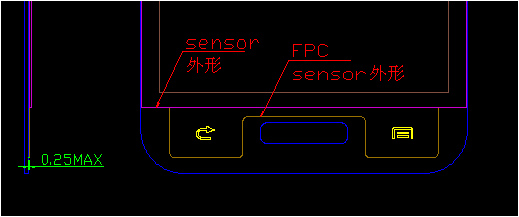

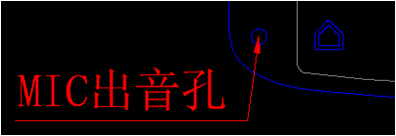

In COVER GLASS, try to reduce the number of through holes as much as possible, because the number of through holes is large, the overall strength decreases, the bad rate rises, and the price rises significantly. In addition, the MIC voice hole is made on COVER GLASS, which is a relatively unsuccessful design and should be avoided as far as possible.

FPC Relevant:

In the design of FPC mechanism, the following aspects are mainly involved:

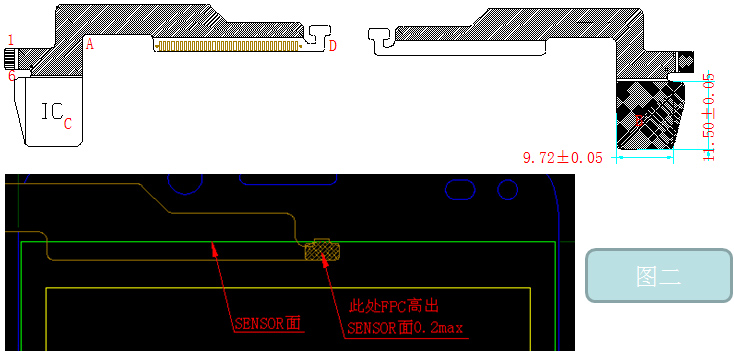

A and FPC bends should be avoided as far as possible in order to improve the yield of installation. As shown in Figure 1.

B. The grounding connection will be made for the steel sheet reinforcement on the back of the component area. It is suggested that the design of the connection between the steel sheet reinforcement and the main board should be added in the whole machine mechanism.

C. In the position of shielding contact line of FPC, the avoidance height of 0.2mm should be considered. In Figure 2 below, particular attention should be paid to the structure of DITO.

FPC Relevant:

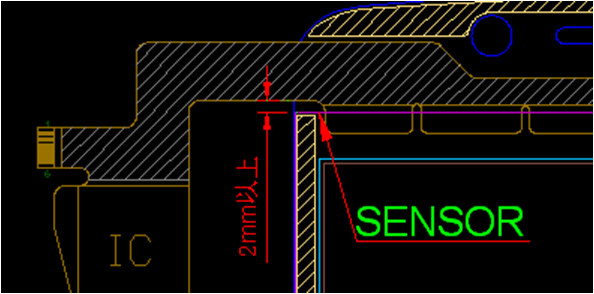

In FPC, due to structural constraints, it is necessary that the FPC be at least 2 mm away from the SENSOR edge.

Relevant to whole stack:

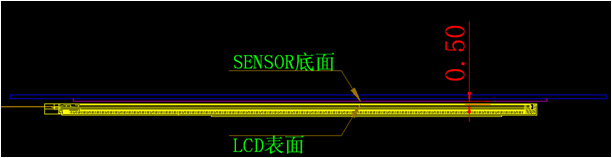

The distance between the bottom of SENSOR and the surface of LCM is guaranteed to be at least 0.3mm. (Incomplete fit product)

The distance between the bottom of SENSOR and the surface of LCM is guaranteed to be at least 0.5mm. (Incomplete fit product)

Capacitance TP IC cloth area should be far away from antenna, Bluetooth, FM, WIFI and other modules to avoid interference.

In ESD protection, CTP should pay attention to the sealing structure between CTP and the casing, and the gap should be as far away as possible from the sensitive areas such as the side line area of CTP. Hearing holes are easy to cause ESD failure. Outgoing FPC should be far away from the sound holes, and the corresponding copper exposure grounding should be done on the FPC.

Touch button:

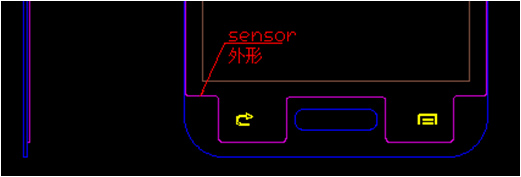

The CTP of G+F architecture can be made into arbitrary shape because of the shape of SENSOR, so the SENSOR of G+F architecture can be made into an integrated structure when making products with physical keyhole. Like following chart:

However, because the SENOR of G + G architecture is GLASS, it can not cut abnormity, so touch keys can only be realized by FPC. As shown in the following figure, touch keys SENSOR and CTP ontology SENSOR are not one or the same plane. Therefore, customers need to pay attention to the case design.